Description

Polyurethane Lined Pipe Is Made Of Carbon Steel Pipe And Polyurethane Lining Material. Polyurethane Has High Abrasion Resistance, High Elasticity And High Corrosion Resistance Characteristic,

So That Pipeline Has Excellent Abrasion Resistance, Acid Resistance, Alkali Resistance, Pollution Resistance, Radiation Resistance, Hydrolysis Resistance, High Elasticity And Mechanical Impact Resistance. Other Comprehensive Performance Of Mechanical Impact Resistance.

Among All Soft Wear-Resistant Materials, Pipe PU Lining Segment Are The Strongest.

Wear Resistant Urethane Lining Pipe Section Can Be Said To Be The Best Choice For Relatively Low Prices. Compared With The Economy Of Rubber Lined Pipe, Polyurethane Liner Has Obvious Advantages.

Be widely used in power, coal, mining, building materials, chemical industries to transport abrasive particles and corrosive media such as fly ash, slag,aluminium, mud and so on.

PU Liner Brief Introduction

Polyurethane Liner Is One Of The Main Wear Resistant Liners In The World (The Other Is Rubber Liner). Due To The Development Of Domestic Wear-Resistant Industry, There Are Many Kinds Of Wear-Resistant Tubes, But The Trend Of Polyurethane Lined Becoming The Mainstream Of Wear-Resistant Industry

Because The Production Technology And Pipe-Forming Technology Of Jinruida Rubber Polyurethane In China Are Very Advanced, Which Can Produce Raw Materials And Have Advanced And Mature Production Technology And Testing Equipment, The Production Cost Of Polyurethane Liner Is Relatively Low.

When The Conveying Medium Is a Fluid Containing Large Particles, Polyurethane Liner Will Be Used Instead Of Polyurethane Liner In The Process Of High-Pressure And High-Speed Transportation.

The Polyurethane Liner Is More Economical And Practical Than The Rubber Liner When The Conveying

Related Polyurethane lined Production:

Reducer

Elbow / Bend

Y Pipe Spooling

Steel Flange

Piping Tee

Spool Work

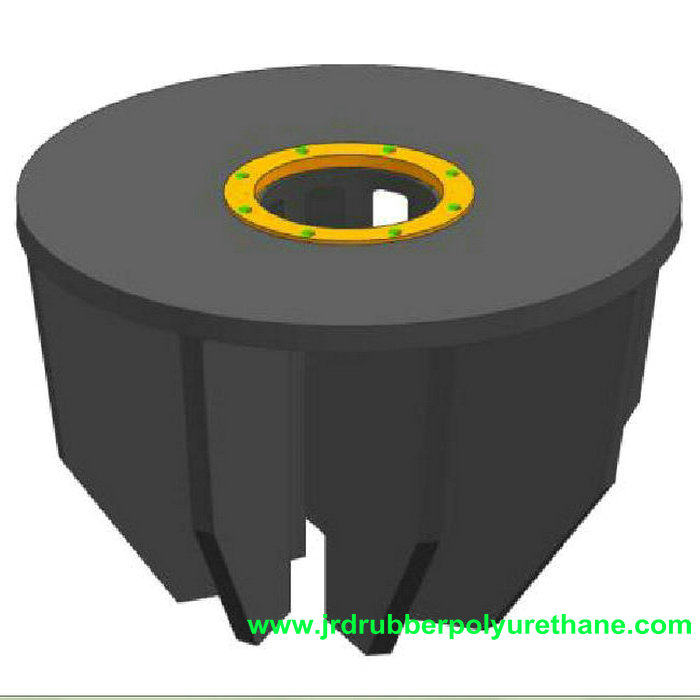

Framework

Fitting

Cross

Frame

Piping Accessories