Description

Hydrocyclone Rubber Liner & Polyurethane Linings Including Of Hydrocyclone Vortex Finder, Hydrocyclone Spigot, Hydrocyclone Nozzle, Hydrocyclone Cone Lining, Hydrocyclone Cylinder Liner.

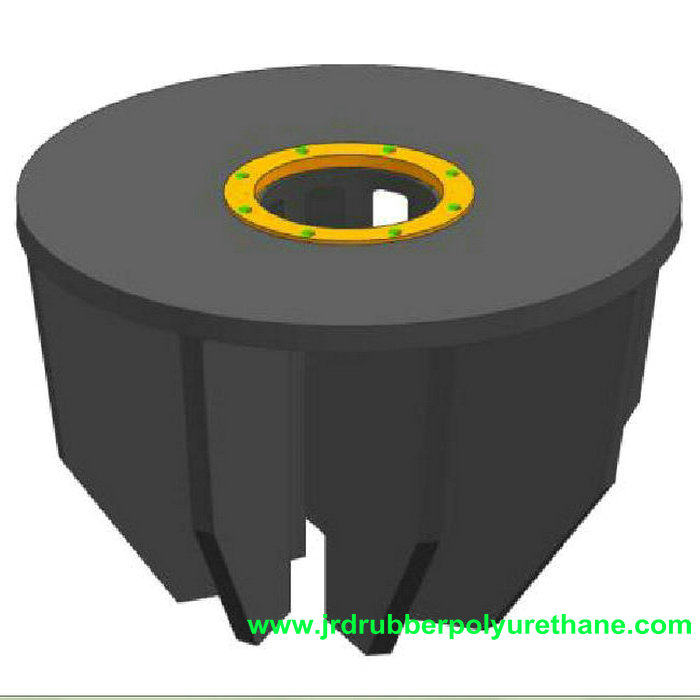

Hydrocyclone Rubber Vortex Finder ( Polyurethane Vortex Finder )

Low Energy Consumption: The Ratio Of Rubber Or Polyurethane Swirlers Is Only 1/7 Of That Of Manganese Steel. The Use Of Wear-Resistant Rubber Or Polyurethane Inner Liner Can Reduce The Quality Of The Cylinder, Thereby Reducing The Load Of The Motor, Saving About 5-10% Of The Electricity, And Reducing The Cost Of Grinding.

High Wear Resistance And Impact Resistance: The Elasticity Of Rubber Or Polyurethane Swirlers Greatly Reduces The Strong Impact Force And Greatly Improves The Wear Resistance. The Service Life Of Rubber Or Polyurethane Swirlers Is About 1.5-2 Times That Of Steel Linings. Within The Grinding Life Of 2-3 Years, The Life Of Two-Stage Grinding Can Reach 4-5 Years.

Low Noise: The Collision Between Steel And Rubber Eddy Current Detector Or Polyurethane Eddy Current Detector Reduces Its Own Noise. The Wear-Resistant Rubber Eddy Current Detector Or Polyurethane Eddy Current Detector Itself Has Sound Insulation Effect, Which Reduces The Noise By More Than 18 Decibels. To a Certain Extent, Noise Reduction Improves The Working Environment, Stimulates The Enthusiasm Of Employees, And Indirectly Improves The Production Efficiency Of Enterprises.

Easy To Install: The Invention Has The Advantages Of Light Weight, Convenient Installation, Short Maintenance Time Of 3/4, Good Sealing Performance, No Slurry Leakage, And Improving Operation Efficiency Of Enterprises.

Corrosion Resistance: Manganese Steel Can Replace Chemical Reaction And React With Acid, Alkali And Salt To Accelerate The Wear Of Liner. The Lining Plate Of JinRuiDa Wear-Resistant Rubber Eddy Current Tester Or Polyurethane Eddy Current Tester Has Special Corrosion Resistance And Prolongs The Service Life Of The Lining Plate.

Effective Volume Is Large And The Processing Capacity Is Large.

Because The Lining Board Of JinRuiDa Rubber Eddy Current Flaw Detector Or Polyurethane Eddy Current Flaw Detector Has High Wear Resistance And The Thickness Of The Designed Lining Board Is Thinner Than That Of Manganese Steel, The Grinding Volume Increases, The Steel Ball Volume Can Be Adjusted Appropriately, And The Processing Ability Of The Mill Is Improved.

Hydrocyclone Spigot

It Is Very Important Parts Of Mining Hydrocyclone Equipment , It Can Protect Cyclone From Demand From Working. For Spigot Always Choose Materials Of High Wear Rubber , Polyurethane (Urethane , Poly , PU) And Silicon Carbide Ceramics ( SiC )

It Is Located At The Bottom Outlet Of The Whole Hydrocyclone. Light Materials Flow Out From The Overflow Pipe Above, And Heavy Materials Flow Out From This Spigot . So it Is The Most Wear-Resistant Part Of The Whole Hydrocyclone. Its Wear Resistance Is Directly Related To The Working Performance And Service Life Of The Whole Set Of Cyclones.

Rubber Spigot Of Hydrocyclone: High Wear-Resistant Rubber, Easy To Install, Shock Absorption, And Can Accept Collision With Outer Steel Pipe.

Hydroyclone Polyurethane Spigot: Wear-Resistant Than Rubber, But Because The Material Itself Is Relatively Hard, Up To 90 Shore a, Not Easy To Install. Normally, It Can Not Be Installed Into The Internal Of The Hydrocyclone By Manual Extrusion. Usually For Small Size Hydrocyclones, Pure Polyurethane Material Is Used.

Silicon Carbide Ceramic Spigot For Hydrocyclone: The Most Wear-Resistant Material Of The Three Materials Is Hard Wear-Resistant Material, Not Soft Material. So It’s Not Seismic And Fragile.

To Sum Up: Because This Spigot Often Has Flange At One End And No Flange At The Other. So The Most Ideal Choice, Of Course, Is a More General Choice In The Industry. Silicon Carbide Ceramics Are Used As Dust Nozzles. However, It Is Also Common To Select Rubber And Polyurethane Materials As Dust Nozzles For Materials With Finer Particles.

Rubber Nozzle

Linear Structure Rubber Nozzle: The General Structure Of Vulcanized Rubber. Because Of Its Large Molecular Weight, It Has a Fine Mass In The Absence Of External Force. When The External Force, The Removal Of The External Force, The Entanglement Of The Fine Mass Changes, The Molecular Chain Bounce, The Emergence Of a Strong Tendency To Recover, This Is The Origin Of High Elasticity Of Rubber.

Branch Chain Structure Rubber Nozzle: The Aggregation Of Branched Chains Of Rubber Macromolecules, Forming Gels. The Gel Has Adverse Effects On The Performance And Processing Of Rubber. In Rubber Refining, All Kinds Of Formulations Often Can Not Enter The Gel Zone, Forming a Local Blank, Forming No Reinforcement And Cross-Linking, Becoming The Weak Part Of The Product.

Hydrocyclone Cone Lining

Hydro Cyclone Cone Lining From JinRuiDa Rubber Polyurethane Manufacture In China Mainly Offer Hydro Cyclone Rubber Cone Lining And Hydro Cyclone Polyurethane Cone Lining For mining hydro cyclone equipment.

Construction Principle: The Conical Liner Of Hydrocyclone Consists Of a Hollow Cylinder At The Top And a Reverse Vertebral Body At The Bottom Connected With The Cylinder To Form a Working Cylinder Of The Conical Liner Of Hydrocyclone. In Addition, The Hydrocyclone Also Has Inlet And Outlet, Draft Tube, Outlet And Mortar.

Hydraulic Cyclone Cone Liner Uses Sand Pump (Or High Difference) To Screw Pulp Into The Drum Along Tangential Direction Under Certain Pressure (Usually 0.5 To 2.5 Kg/Cm) And Flow Rate (About 5 To 12 m/Sec).

Then, The Mud Rotates Along The Cylinder Wall At a Very Fast Speed, Resulting In Centrifugal Force. Under The Action Of Centrifugal Force And Gravity, Coarser And Heavier Ore Particles Are Thrown Out.

The Cone Lining Of Hydrocyclone Is Mainly Used For Classification, Separation, Concentration And Desliming In Mineral Processing Industry.

When The Hydrocyclone Cone Lining Is Used In The Classifying Equipment, The Grinding And Classification System Is Formed Together With The Mill.

When The Cone Lining Of Hydrocyclone Is Used For Desilting Equipment, It Can Be Used For Desilting In Gravity Separation Device.

When Hydrocyclone Cone Lining Is Used In Beneficiation And Dewatering Equipment, Tailings Can Be Concentrated And Then Sent To Underground Mining Tunnels For Filling.

The Suspension Enters The Hydrocyclone At a Higher Speed From The Feed Pipe Along The Tangent Direction. Limited By The Outer Cylinder Wall, The Liquid Is Forced To Rotate From Top To Bottom. Usually, This Motion Is Called External Eddy Current Or Downward Eddy Current Motion.

No Moving Parts, Simple Structure.

The Unit Volume Production Capacity Is Large And The Area Is Small.

The Classification Efficiency Is High (80% – 90%) And The Classification Granularity Is Fine.

Low Cost, Less Material Consumption.

Hydrocyclone Cylinder Liner

Hydro Cyclone Cylinder Lining Produced By Jinruida Rubber Polyurethane Company In China Mainly Provides The Rubber Cylinder Lining Of Hydrocyclone And Polyurethane Cylinder Lining Of Hydrocyclone For Mine Hydrocyclone Equipment.

Rubber Cylinder Lining And Polyurethane Cylinder Lining Refer To The Use Of Natural Rubber And Synthetic Polyurethane Rubber To Produce a Variety Of Rubber Or Polyurethane, And Waste Rubber Or Polyurethane To Produce Rubber Or Polyurethane Products.

Performance Of Rubber Polyurethane Cylinder Lining

1. When The Rubber Cylinder Is Formed, The Cohesion Of The Elastomer Cannot Be Eliminated By The Pressure Of The Elastomer. In The Forming Process, It Is Often Very Unstable Shrinkage Of Hydraulic Cyclone Lining (Due To Rubber Shrinkage, Because The Rubber Is Different), It Must Take a Period Of Time To Stabilize.

Therefore, When Designing a Rubber Drum At The Beginning Of The Design, Both The Formula And The Die Should Be Carefully Calculated. Otherwise, The Size Of The Rubber Lining Will Be Unstable And The Quality Of The Rubber Lining Will Be Poor.

Rubber Cylindrical Thermosetting Elastomer, Plastic Belongs To Thermosetting Cooling. Because Of The Different Kinds Of Sulfides, The Temperature Range Of Forming And Curing Is Also Very Different. Even Due To Climate Change, Indoor Temperature And Humidity Will Be Affected. Therefore, It Is Necessary To Adjust The Situation Of Rubber Ring Lining Product Line At Any Time. Otherwise, The Quality Of Rubber Lining May Vary.

Rubber Hydrocyclone Cylinder Is Made Of Rubber Raw Materials Produced By Rubber Refinery. In The Processing Of Rubber Lining, The Formula Was Designed According To The Performance Of The Rubber Ring And The Required Hardness Was Determined. The Forming Process Is Formed By Rubber Plate Vulcanizing Machine. Finally, The Rubber Parts Are Flash Processed To Make The Rubber Surface Smooth And Burr-Free.

Rubber Liner Of Hydrocyclone Is Mainly Made Of Wear-Resistant Natural Rubber. The Information Of Wear-Resistant Natural Rubber Is As Follows:

Natural Characteristics Of Rubber Cylindrical Lining

Wear-Resistant Natural Rubber Is The Milk Produced By Artificial Cultivation Of Clover Rubber Tree. It Is Made By Solidification And Processing. The Main Ingredient Is Polyisoprene, The Content Is More Than 90%. In Addition, It Contains a Small Amount Of Protein, Fat, Acid, Sugar And Ash.